I-Yc-8101a Isimbozo Se-Ceramic Esinganamatheli Esiphezulu Se-Porcelain Nano-composite (Esimnyama)

Izingxenye zomkhiqizo kanye nokubukeka

(Ukugqoka kwe-ceramic okunezingxenye ezimbili)

I-YC-8101A-A:Isembozo se-Component A

I-YC-8101A-B: I-ejenti yokwelapha ingxenye ye-B

Imibala ye-YC-8101:okubonakalayo, okubomvu, okuphuzi, okuluhlaza okwesibhakabhaka, okumhlophe, njll. Ukulungiswa kombala kungenziwa ngokwezidingo zamakhasimende

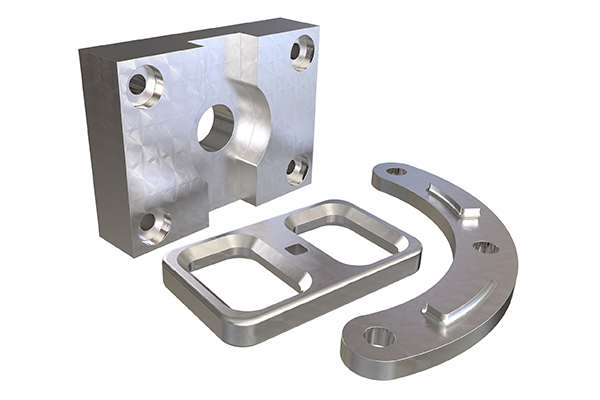

I-substrate esebenzayo

Izindawo ezingaphansi komhlaba ezahlukahlukene ezifana namapani anganamatheli zingenziwa ngensimbi, insimbi ethambile, insimbi yekhabhoni, insimbi engagqwali, i-aluminium alloy, i-titanium alloy, insimbi ye-alloy eshisa kakhulu, ingilazi ye-microcrystalline, i-ceramics, nezinye izinhlobo ze-alloy.

Izinga lokushisa elisebenzayo

- Ukumelana nokushisa okuphezulu kakhulu kungu-800℃, kanti izinga lokushisa lokusebenza kwesikhathi eside lingaphakathi kuka-600℃. Limelana nokuguguleka okuqondile ngamalangabi noma ukugeleza kwegesi okushisa okuphezulu.

- Ukumelana nokushisa kwesembozo kuzohluka ngokufanele kuye ngokumelana nokushisa kwezingxenye ezahlukene. Kumelana nokubanda kanye nokushaqeka kokushisa kanye nokudlidliza kokushisa.

Izici zomkhiqizo

- 1. Izimbozo ezincane zisekelwe emanzini kuphela, ziphephile, zinobungani nemvelo futhi azinabo ubuthi.

- 2. I-Nano-composite ceramics ithola i-vitrification eqinile futhi ebushelelezi ekushiseni okuphansi okungu-250℃, okuyonga amandla futhi okujabulisa ubuhle.

- 3. Ukumelana namakhemikhali: Ukumelana nokushisa, ukumelana ne-asidi, ukumelana ne-alkali, ukuvikela ukushisa, ukumelana nokushisa okuphezulu, kanye nokumelana nemikhiqizo yamakhemikhali, njll.

- 4. Isembozo simelana namazinga okushisa aphezulu kanye nokushaqeka kokushisa ngaphakathi kobukhulu obuthile (cishe ama-micron angu-30), futhi simelana kahle nokushaqeka kokushisa (simelana nokushintshana kokushisa, futhi asiqhekeki noma siqhekeke ngesikhathi sokusebenza kwesembozo).

- 5. Isembozo esingenazinto eziphilayo siminyene futhi sisebenza kahle ekuvikeleni ugesi, sine-voltage ekwazi ukumelana nokuvikela ugesi engaba ngu-1000 volts.

- 6. Inokushisa okuzinzile nokuhle kanye namandla amahle kakhulu okubopha.

- 7. Ubulukhuni: 9H, ukumelana namalangabi avulekile kanye namazinga okushisa aphezulu afinyelela kuma-degrees angu-400, ukukhanya okuphezulu, kanye nokumelana nokuguguleka okuphezulu

Izinkambu zohlelo lokusebenza

1. Izingxenye zebhoyila, amapayipi, amavalvu, ama-heat exchanger, ama-radiator;

2. Ingilazi encane ecwebezelayo, amathuluzi nemishini, amadivayisi ezokwelapha, imishini yemithi, kanye nemishini yezakhi zofuzo eziphilayo;

3. Amadivayisi okushisa okuphezulu kanye nezingxenye zenzwa yokushisa okuphezulu;

4. Izindawo zemishini yensimbi, isikhunta, kanye nemishini yokukhipha;

5. Izinto zokushisa zikagesi, amathangi, namabhokisi;

6. Izinto zasendlini ezincane, izinto zasekhishini, njll.

7. Izingxenye ezishisa kakhulu zezimboni zamakhemikhali nezensimbi.

Indlela yokusebenzisa

(Ukuqinisekisa imiphumela emihle, kutuswa ukuyisebenzisa ngale ndlela elandelayo)

1. Izingxenye ezimbili:Vala bese ulungisa ngesilinganiso sesisindo esingu-2:1 amahora amabili kuya kwamathathu. Isembozo esilungisiwe sibe sesihlungwa ngesikrini sesihlungi esingu-400-mesh. Isembozo esihlungiwe siba isembozo se-ceramic esiqediwe futhi sibekelwa eceleni ukuze sisetshenziswe kamuva. Upende osele kufanele usetshenziswe zingakapheli amahora angama-24; ngaphandle kwalokho, ukusebenza kwawo kuzoncipha noma kuqine.

2. Ukuhlanza izinto eziyisisekelo:Ukususa amafutha nokugqwala, ukugoba ubuso kanye nokuqhuma kwesihlabathi, ukuqhuma kwesihlabathi nge-Sa2.5 grade noma ngaphezulu, umphumela omuhle kakhulu utholakala ngokuqhumisa isihlabathi nge-46-mesh corundum (i-corundum emhlophe).

3. Izinga lokushisa lokubhaka: 270℃ imizuzu engama-30 (Ingalapheka ekushiseni kwegumbi. Ukusebenza kokuqala kubi kancane, kodwa ingabuyela esimweni esijwayelekile ngokuhamba kwesikhathi.)

4. Indlela yokwakha Ukufutha:Ingxenye yokusebenza okufanele ifuthwe kufanele ishiswe ngaphambi kokushisa okungaba ngu-40°C; ngaphandle kwalokho, kungase kube nokuwa noma ukushwabana. Kunconywa ukuthi ubukhulu bokufafaza bube ngaphakathi kwama-microns angu-30. Kungafuthwa kanye kuphela.

5. Ukwelashwa kwamathuluzi okumboza kanye nokwelashwa kokumboza

Ukuphatha amathuluzi okumboza: Hlanza kahle nge-ethanol engenamanzi, yomise ngomoya ocindezelwe bese uyigcina.

6. Ukwelashwa kokumboza: Ngemva kokufutha, yiyeke yome ngokwemvelo phezu kwamanzi cishe imizuzu engama-30. Bese uyibeka kuhhavini oshisiwe kuma-degrees angu-250 bese uyigcina ifudumele imizuzu engama-30. Ngemva kokuphola, yikhiphe.

Ihlukile ku-Youcai

1. Ukuzinza kobuchwepheshe

Ngemva kokuhlolwa okuqinile, inqubo yobuchwepheshe be-nanocomposite ceramic yezinga lezindiza ihlala izinzile ngaphansi kwezimo ezimbi kakhulu, imelana namazinga okushisa aphezulu, ukushaqeka kokushisa kanye nokugqwala kwamakhemikhali.

2. Ubuchwepheshe bokuhlakazeka kwe-Nano

Inqubo yokuhlakazeka eyingqayizivele iqinisekisa ukuthi ama-nanoparticles asatshalaliswa ngokulinganayo embozweni, kugwenywe ukuhlangana. Ukwelashwa okusebenzayo kwe-interface kuthuthukisa ukuhlangana phakathi kwezinhlayiya, kuthuthukise amandla okuhlangana phakathi kwembozo kanye ne-substrate kanye nokusebenza okuphelele.

3. Ukulawulwa kokumboza

Ukwakheka okunembile kanye namasu ahlanganisiwe kwenza ukusebenza kokumboza kukwazi ukulungiswa, njengokuqina, ukumelana nokuguguleka kanye nokuqina kokushisa, okuhlangabezana nezidingo zezinhlelo zokusebenza ezahlukene.

4. Izici zesakhiwo se-Micro-nano:

Izinhlayiya ze-ceramic ezihlanganisiwe zigoqa izinhlayiya ze-micrometer, zigcwalise izikhala, zakhe uqweqwe oluqinile, futhi zithuthukise ukuqina nokumelana nokugqwala. Okwamanje, izinhlayiya ezincane zingena ebusweni be-substrate, zakha i-interphase yensimbi-ceramic, ethuthukisa amandla okubopha kanye namandla aphelele.

Umgomo wocwaningo nentuthuko

1. Inkinga yokuqhathanisa ukunwetshwa kokushisa:Ama-coefficient okwandisa ukushisa kwezinto zensimbi neze-ceramic avame ukuhluka ngesikhathi sokushisa nokupholisa. Lokhu kungaholela ekwakhekeni kwama-microcracks embozweni ngesikhathi senqubo yokujikeleza kokushisa, noma ngisho nokuqhekeka. Ukuze kuxazululwe le nkinga, u-Youcai uthuthukise izinto ezintsha zokugqoka ezi-coefficient zokwandisa ukushisa eziseduze ne-substrate yensimbi, ngaleyo ndlela kunciphisa ukucindezeleka kokushisa.

2. Ukumelana nokushaqeka kokushisa kanye nokudlidliza kokushisa: Uma ungqimba lwensimbi lushintsha ngokushesha phakathi kwamazinga okushisa aphezulu naphansi, kumele lukwazi ukumelana nokucindezeleka kokushisa okubangelwa yilokhu ngaphandle kokulimala. Lokhu kudinga ukuthi ungqimba lube nokumelana okuhle kakhulu nokushaqeka kokushisa. Ngokwenza ngcono isakhiwo se-microstructure yengqimba, njengokwandisa inani lezindawo zokuhlangana zesigaba nokunciphisa usayizi wezinhlamvu, i-Youcai ingathuthukisa ukumelana kwayo nokushaqeka kokushisa.

3. Amandla okubopha: Amandla okubopha phakathi kwengubo kanye ne-substrate yensimbi abalulekile ekuzinzeni nasekuqineni kwesikhathi eside kwengubo. Ukuze kuthuthukiswe amandla okubopha, i-Youcai yethula ungqimba oluphakathi noma ungqimba lokuguquka phakathi kwengubo kanye ne-substrate ukuze kuthuthukiswe ukumanzi kanye nokubopha kwamakhemikhali phakathi kwalokhu okubili.