Izibizo zomkhiqizo

Upende we-alkyd, i-alkyd top coat, upende we-alkyd, upende we-alkyd anticorrosive, i-alkyd anticorrosive top coat, i-alkyd magnetic top coat.

Amapharamitha ayisisekelo

| Igama Lomkhiqizo WesiNgisi | Ijazi eliphezulu le-Alkyd |

| Igama Lomkhiqizo WesiShayina | Ijazi Eliphezulu Le-Alkyd Magnetic |

| Izimpahla Eziyingozi Cha. | 33646 |

| Inombolo ye-UN | 1263 |

| Ukuguquguquka kwe-solvent ye-organic | Imitha ejwayelekile engu-64³. |

| Umkhiqizo | Imidwebo kaJinhui |

| Inombolo Yemodeli | C52-5 |

| Umbala | Umbala |

| Isilinganiso sokuxuba | Ingxenye eyodwa |

| Ukubukeka | Ubuso obubushelelezi |

Ukwakheka komkhiqizo

I-Alkyd Magnetic Paint iyipende elinobuthi elenziwe nge-alkyd resin, izithasiselo, uphethiloli we-solvent ongu-No.200 kanye nezinyibilikisi ezixubile, kanye ne-dryer agent.

Izici

- Ukumelana nefilimu yokupenda ekushiseni, ukusebenza kahle kokuvikela, ukugcina ukukhanya okuhle kanye nokugcina umbala, umbala okhanyayo, ukuqina okuhle.

- Inamathela kahle ensimbini nasezinkunini, futhi inokumelana namanzi athile kanye nokumelana namanzi anosawoti.

- Ifilimu yopende eqinile, ukuvala okuhle, ukusebenza okuhle kakhulu kokulwa nokugqwala, ingamelana nomthelela wokwehluka kwezinga lokushisa.

- Ukumelana nesimo sezulu okuhle, ukucwebezela nokuqina.

- Okuqukethwe okuphezulu kombala, ukusebenza kahle kokusikwa.

- Ukunamathela okuqinile, izakhiwo ezinhle zemishini.

- Ikhono lokugcwalisa eliqinile.

- Ukusebenza kahle kokwakhiwa.

Amapharamitha obuchwepheshe: GB/T 25251-2010

- Isimo esitsheni: akukho zigaxa eziqinile ngemva kokuxuba nokuxuba, esimweni esifanayo.

- Ubuncane: ≤40um (inkomba ejwayelekile: GB/T6753.1-2007)

- Ukumelana namanzi anosawoti: 3% NaCl, amahora angu-48 ngaphandle kokuqhekeka, ukubhamuka noma ukuxebuka (Inkomba ejwayelekile: GB/T9274-88)

- Okuqukethwe kwezinto ezingaguquki: ≥50% (inkomba ejwayelekile: GB/T1725-2007)

- Ukumelana namanzi: amahora angu-8 ngaphandle kokuqhekeka, ukubhamuka noma ukuxebuka (Inkomba ejwayelekile: GB/T9274-88)

- Isikhathi sokomisa: ukomisa ubuso ≤ amahora angu-8, ukomisa kwangempela ≤ amahora angu-24 (inkomba ejwayelekile: GB/T1728-79)

Ukwelashwa kwendawo

Ukwelashwa kokuqhumisa isihlabathi ebusweni bensimbi kuya ezingeni le-Sa2.5, ubulukhuni bendawo bungu-30um-75um.

Amathuluzi kagesi ehla aye ebangeni lika-St3.

Ukufanisa inkundla yangaphambili

I-primer ye-alkyd, upende ophakathi we-alkyd mica.

Imingcele yokwakha

| Ubukhulu befilimu obunconyiwe | 60-80um |

| Isilinganiso semfundiso | cishe i-120g/m² (ngokusekelwe kufilimu eyomile engu-35um, ngaphandle kokulahlekelwa) |

| Inani elinconywayo lamajazi | Amajazi ama-2~3 |

| Izinga lokushisa lesitoreji | -10~40℃ |

| Izinga lokushisa lokwakha | 5~40℃. |

| Isikhathi sesivivinyo | Amahora angu-6 |

| Indlela yokwakha | Ukuxubha, ukufutha ngomoya, ukugoqa kungaba. |

| Isikhawu sokumboza | Izinga lokushisa le-substrate ℃ 5-10 15-20 25-30 |

| Isikhawu esifushane h 48 24 12 | |

| Isikhathi eside akufanele sidlule izinsuku eziyi-7. | |

| Izinga lokushisa le-substrate kumele libe ngaphezu kuka-3℃ ngaphezu kwephuzu lamazolo, uma izinga lokushisa le-substrate liphansi kuka-5℃, ifilimu yopende ngeke ilapheke futhi akufanele yakhiwe. | |

Ukwakhiwa kokupenda

Ngemva kokuvula umgqomo, kumele uvuselelwe ngokulinganayo, uyekwe ukuze ume, bese kuthi ngemva kokuvuthwa imizuzu engama-30, wengeze inani elifanele lokunciphisa bese ulungisa ukuqina kokwakhiwa.

I-Diluent: i-diluent ekhethekile yochungechunge lwe-alkyd.

Ukufutha okungenamoya: Inani lokuxuba lingu-0-5% (ngokwesilinganiso sesisindo sopende), ubukhulu be-nozzle bungu-0.4mm-0.5mm, ingcindezi yokufutha ingu-20MPa-25MPa (200kg/cm²-250kg/cm²).

Ukufutha ngomoya: Inani lokuxuba lingu-10-15% (ngokwesilinganiso sesisindo sopende), ubukhulu be-nozzle bungu-1.5mm-2.0mm, ingcindezi yokufutha ingu-0.3MPa-0.4MPa (3kg/cm²-4kg/cm²).

Ukumbozwa kwe-roller: Inani lokuxuba lingu-5-10% (ngokwesilinganiso sesisindo sopende).

Ukusetshenziswa

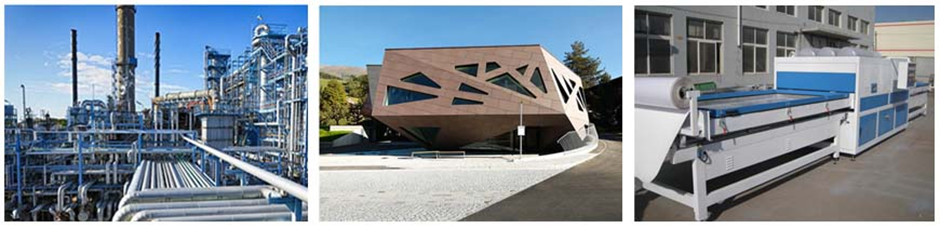

Ifanelekela izindawo zensimbi, izindawo zomshini, izindawo zamapayipi, izindawo zemishini, izindawo zokhuni, izindawo zensimbi zangaphakathi nangaphandle kanye nezindawo zokhuni ukuvikela nokuhlobisa, iyipende elisetshenziswa kabanzi, elisetshenziswa kabanzi ekwakheni, emishinini, ezimotweni nasezimbonini ezahlukene zokuhlobisa.

Inothi

Ukufutha okomile kungenzeka ngesikhathi sokushisa:

- Esikhathini sokushisa okuphezulu sokwakha, kulula ukomisa isifutho, ukuze kugwenywe isifutho esomile kungalungiswa nge-thinner kuze kube yilapho isifutho esomile singashisi.

- Lo mkhiqizo kufanele usetshenziswe ngabasebenzi bokupenda abangochwepheshe ngokwemiyalelo esephaketheni lomkhiqizo noma kule ncwadi.

- Konke ukumbozwa nokusetshenziswa kwalo mkhiqizo kumele kwenziwe ngokuhambisana nayo yonke imithetho nezindinganiso ezifanele zezempilo, ukuphepha kanye nezemvelo.

- Uma ungabaza ukuthi uzowusebenzisa yini lo mkhiqizo noma cha, sicela uxhumane nomnyango wethu wezinsizakalo zobuchwepheshe ukuthola imininingwane.

Ukupakisha

Isigubhu esingama-25kg.

Ezokuthutha kanye nesitoreji

Umkhiqizo kufanele ugcinwe endaweni epholile futhi enomoya, uvinjelwe elangeni eliqondile, futhi uhlukaniswe nemithombo yokushisa, kude nemithombo yokushisa esendlini yokugcina impahla.

Uma uthutha umkhiqizo, kufanele uvinjelwe emvuleni, ekuchayekeni elangeni, ugweme ukushayisana, futhi kufanele uhambisane nemithethonqubo efanele yomnyango wezokuthutha.

Ukuvikelwa Kokuphepha

Indawo yokwakha kufanele ibe nezindawo ezinhle zokungenisa umoya, futhi abapendi kufanele bagqoke izibuko, amagilavu, imaski, njll. ukuze bagweme ukuthintana kwesikhumba kanye nokuhogela inkungu yopende.

Intuthu nomlilo akuvunyelwe ngokuphelele endaweni yokwakha.

Imibuzo Evame Ukubuzwa Yikhasimende

Kulula yini ukupenda ama-topcoat amhlophe nanombala okhanyayo ngemva kokusebenzisa i-Iron Red Anti-Rust?

A: Ama-enamel ajwayelekile e-alkyd awakwazi ukufakwa ezindaweni ezingenhla.

Ingabe i-topcoat ingapendwa phezu kwepulasitiki, i-aluminium kanye nezindawo ezifakwe i-galvanised?

A: Cha, akulula, udinga ukufaka ezinye izimbobo ezimbili ze-topcoat.

Ukwakhiwa kanye nokugcinwa kanye nokuthuthwa

1. Ngokusho kokwakhiwa, sebenzisa i-alkyd thinner ukulungisa i-viscosity.

2. Upende ungaxutshwa, ugoqwe noma ufafazwe.

3. Ngaphambi kokwakha, kufanele kususwe i-substrate yamafutha, ukungcola, uthuli kanye nokugqwala. Umswakama ohlobene ongaphezu kuka-85% akufanele wakhiwe, abasebenzi bokwakha kufanele baqinise ukuvikelwa kwabo, bagqoke izingubo zokuphepha ezinhle ukuvimbela inkungu yopende ephefumulayo futhi ifafazwe esikhumbeni.

4. Umkhiqizo kufanele ubekwe endaweni yokugcina impahla eyomile nepholile, isikhathi sokuphila seshelufu sezinyanga ezingu-12. 5. Inqubo yokugcina kanye nokuthutha kufanele ivinjelwe ngokuphelele ukushayisana, ilanga, imvula, futhi kude nemithombo yomlilo.

Inkomba yokwakha:

- Ukufutha: umfutho womoya 0.3 ~ 0.4 Mpa viscosity 18 ~ 22 S / upende -4 izinkomishi

- Ibhulashi: iyasebenza

- Isithambisi: isithambisi esikhethekile

- Ukusetshenziswa kwethiyori: 110 ~ 130g/imitha yesikwele

- I-primer ehambisanayo: i-primer ye-alkyd ebomvu yensimbi, upende we-ferric alkyd olwa nokugqwala, njll.

- Izinyathelo zokuphepha: Lo mkhiqizo ungasha, ugcinwa futhi wakheke, unake umoya, uphola, futhi uqhelelene nomlilo.

- Indawo Yokugcina: Gcina endaweni epholile neyomile, isikhathi sokugcina esisebenzayo sonyaka owodwa. Uma isikhathi sokugcina sidlula unyaka owodwa, umkhiqizo ungasetshenziswa uma uhlangabezana nezidingo ngemuva kokuhlolwa.

- Ukufutha, ukuxubha kungaba, komile noma komile ekamelweni lokushisa (izinga lokushisa lokomisa lingu-60-70 degrees)

- Ubukhulu besendlalelo ngasinye bungama-micron angu-15-20, okokuqala komile bese kuthi okwesibili kusetshenziswe.

- Ingancishiswa nge-turpentine kanye namafutha e-petroleum solvent angu-200# kanye ne-xylene nezinye izinyibilikisi.

- Izidingo zopende we-alkyd magnetic: faka i-alkyd primer kuqala bese usebenzisa i-alkyd putty ukuze wenze ubushelelezi, bese ekugcineni faka upende we-alkyd magnetic.